Carbon-Composites

Voith Composites produces a wide variety of different products made from fibre composites such as, for example, ships' propellers, components for the automotive industry and industrial products such as rollers and cylinders for paper machines and additional systems engineering. In this case it concerns a processing unit for the production of high-precision guide rollers made from carbon-fibre reinforced plastic. These rollers are used in high-precision cutting machines as machine elements.

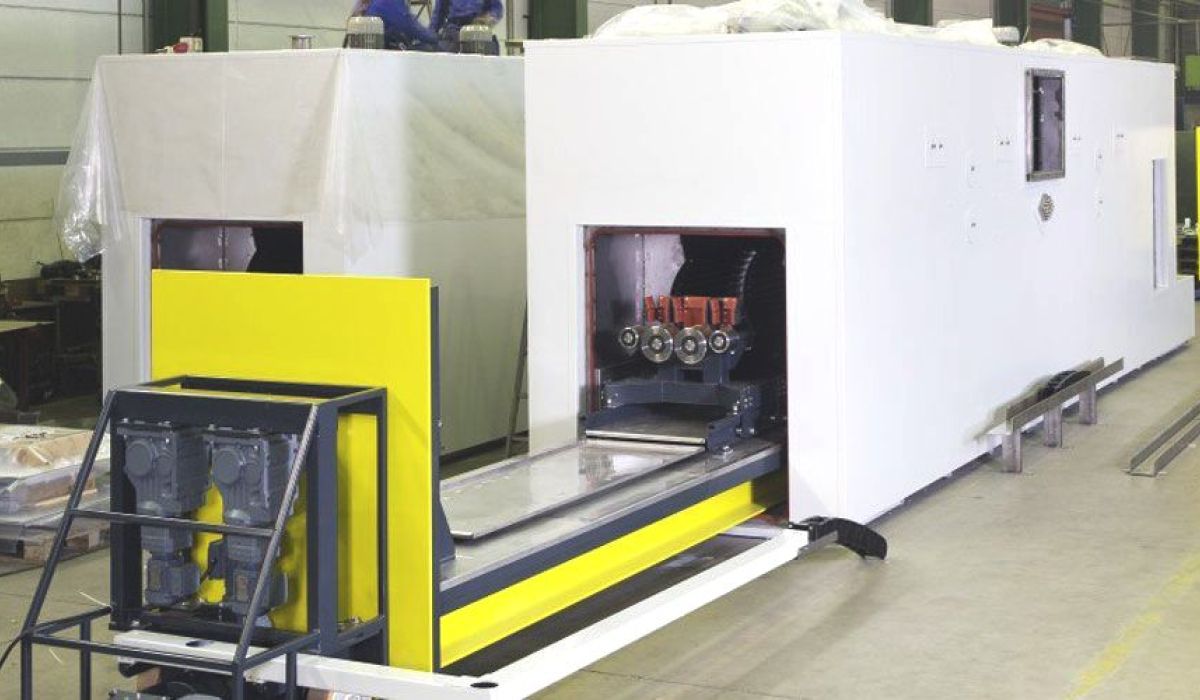

Wrapping and annealing

For the production of the carbon rollers Münstermann designed and developed three annealing ovens, which come into operation twice. First the long pins, also known as cores, are heated up in the oven. The pins are then wrapped with carbon fibre by a winding machine and again moved into the oven so that the fibres soaked in resin are set hard. The oven is equipped with a loading system over which many wrapped pins of differing size can be thermally treated.

Material handling and control system

Having been passed through the heating treatment process the pins are taken out of the oven and the finished carbon rollers are removed from the pins by means of a so-called pin extraction device. After that the rollers are cut to the required length. Apart from the winding machines and the saws, Münstermann has supplied all machine components such as, for example, the pin-handling device. The overall control system has also been designed and developed by Münstermann. The all-round carefree package for the customer is rounded off in that both the safety concept of, for example, the control of the safety and access areas as well as the CE-certification of the whole unit (also for the components not supplied by Münstermann such as the saws and winding machine) can be taken over by us.