Münstermann offers drum dryers for a variety of applications. The production process know how in this sector is broadened with the addition of Dörfler’s many years of experience. Münstermann takes on the execution of everything from the project management to the commissioning of the project. For technical and commercial questions, please contact Thomas Dörfler directly at +49 5492 982030 or

Special features of our drum dryers

The dyers supplied by us are characterized by a very gentle drying process at temperatures between 80 and 800 °C. The one-drum or three-drum system of our dryers can be used for a wide variety of products and guarantees perfect handling of the product to be dried.

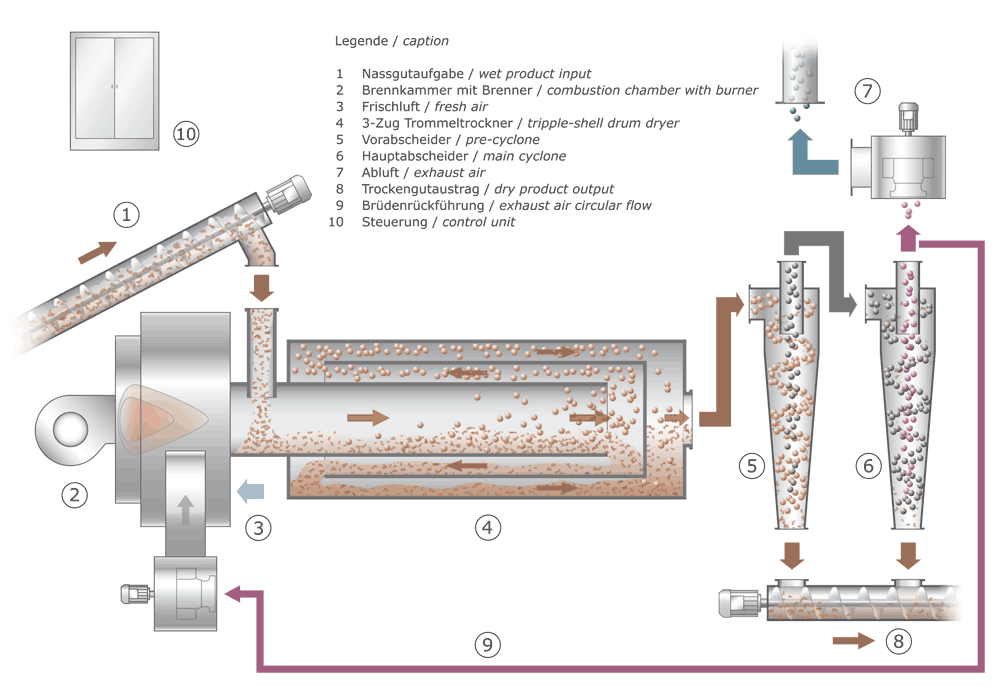

Our units are fitted with a specially designed burner for the drying mode for each type of fuel. Different types of fuel can be supplied. Well-designed conveying and separating systems ensure trouble-free operation. A sketch of the principle of operation is shown in the figure below. This includes not only the dryer but also the de-dusting.

Not only drying but also dedusting

Of course, in addition to the actual drum dryer Münstermann offers the appropriate dedusting and air pollution control. For you as a customer, this means one less interface in an overall project. An example is described in the following article: {flexi_link:item title:"Dedusting of a drum dryer during the processing of coal treatment"}

A variety of application

Drum dryers can be used for many different applications. Be it for the drying of bulk materials like catalysts, sand, clay, quartz sand, ferrous sulphate or for the drying of pomace, wood chippings, animal feeds and other foodstuffs or fermentation residues from, for example, biogas units, drum dryers have their applications in the most differing industries.