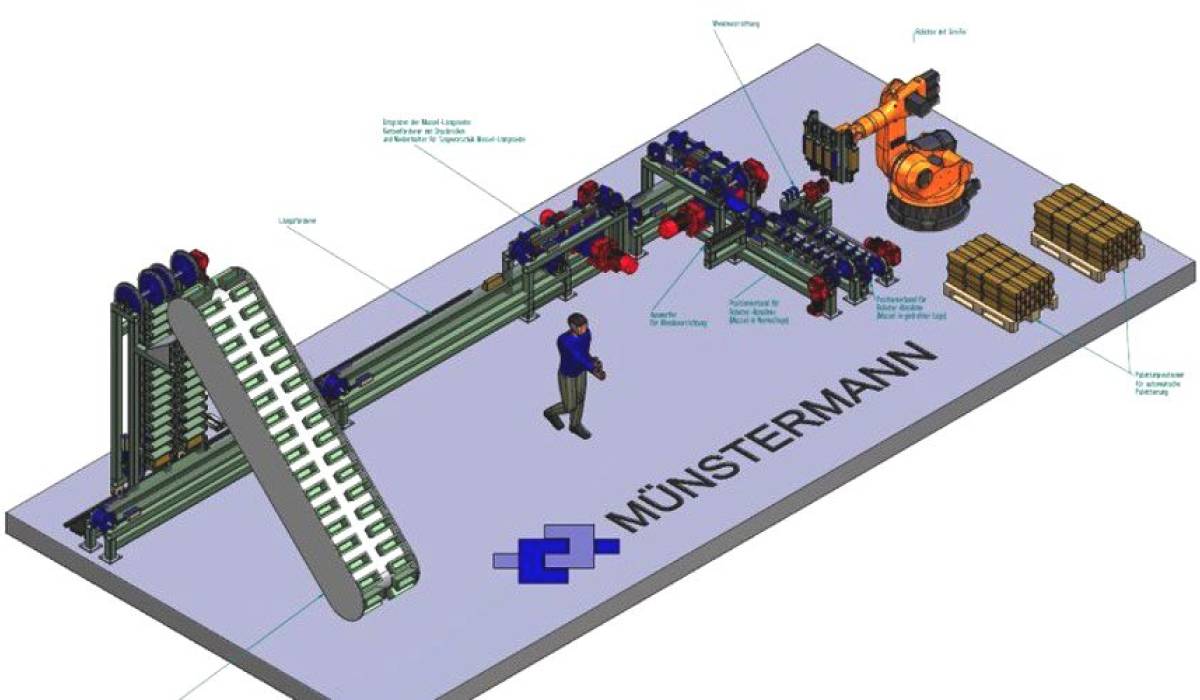

Handling and processing unit for ingots

When looking at the heading one asks oneself arbitrarily what are ingots and how are they produced? In this case ingots are metal bars, mostly out of light or non-ferrous metals such as brass, copper, aluminium or zinc.

Read more …