Plate curing in 4 hours: Münstermann has supplied a further two curing chambers for battery plates. The unites operate according to the Concure-Process. The Concure-Process is a patented rapid curing process, in which the plates are not cured in the conventional process in 30 hours, but are cured in the chambers in only 4 hours.

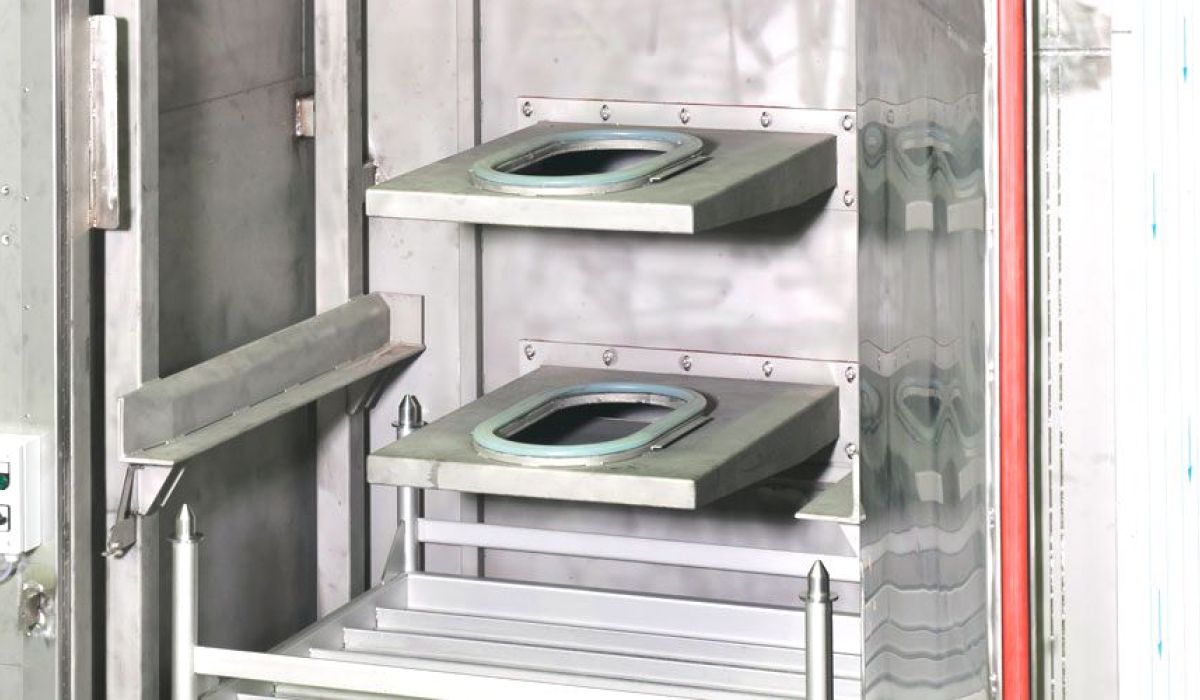

New curing chambers

A curing chamber oven is currently being supplied to both Willard Batteries and an Asiatic producer. The loading capacity of the ovens amounts to 37,000 plates per curing process. The duration of the curing process is 4 hours so that with the loading and unloading of the ovens a period of approximately 5 hours for the complete curing process results.

The Concure-Rapid Curing Process has, meanwhile, been successfully in operation and proven in practice with six battery producers for years and several of these firms employ conventional curing ovens from Münstermann).

Advantages of the process

Along with the rapid curing there are further potential advantages for the Concure-Curing Chambers partly connected with the speed of processing:

- Important 'Just-in-time' deliveries: intermediate storage of the plates is no longer necessary with a short curing time

- The process can be quickly shifted to different products

- The investment costs can be halved: investments in a conventional curing process can be double that of the Concure-Chambers with the same production capacity.

- The quality of the curing is not affected by the speed of curing

Should you be interested the basis of these statements can be explained in more detail.