As part of the modernisation of its glass wool production, Superglass in Stirling (Scotland) had the white wool forming section replaced by Münstermann.

Including air treatment

In addition to the white wool forming section, Münstermann supplied for the first time a self-developed scrubber system for exhaust air treatment.

Optimized fiber distribution

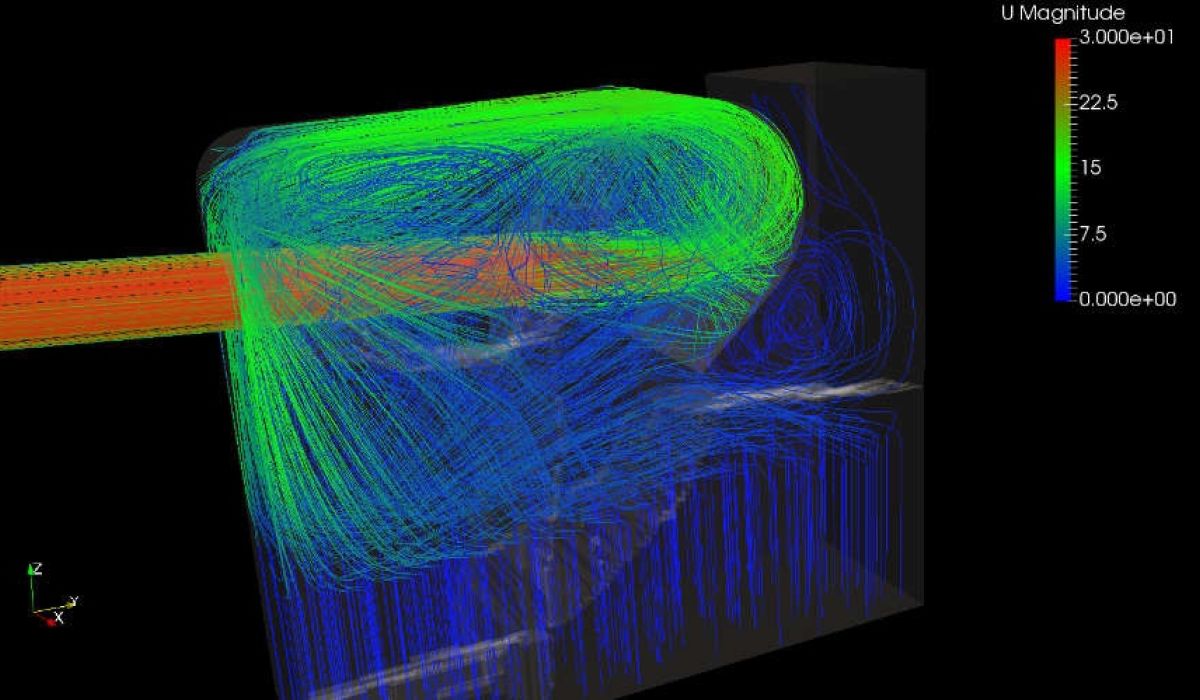

The glass wool fibres, which are produced with three fiberizing machines, are transported via a collecting pipe over the rear wall into the white wool forming section. A built-in deflector plate in the upper section guarantees optimum distribution of the fibres as they enter the forming sections. Our R&D department carried out flow simulations and tests in our test centre to ensure optimum distribution.