Our MFS range of reverse air filters comprises a series of modular filter units up to 2,000 m² filtration area. The filter system provides continuous automatic reverse air cleaning with a constantly low filter differential pressure at extremely low operating cost, and a long service life. Large front doors enable a quick and easy access for maintenance operations.

Functional description

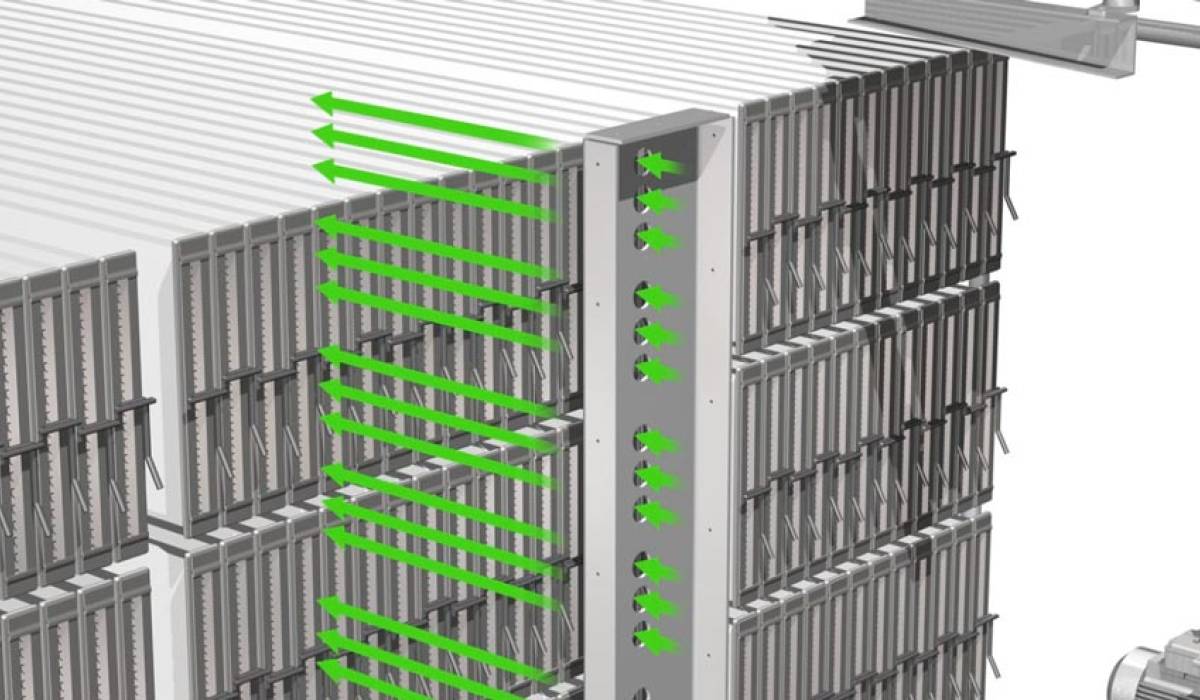

The surface filter MFS operates fully automatically with a reverse air cleaning system. This custom-made filter allows economic operation with a constantly low filter differential pressure. The blowing impulses are generated by an impulse transmitter in a fixed position. This transmitter is fed by an impulse air fan and the transmission of the cleaning impulses to the mobile cleaning trolley is effected via a flexible metal tube.

Design

The filter housing is constructed of reinforced welded steel sheet. Airtight doors allow access to the clean gas chamber. The filter element consists of individual filter bags and inserts with spanners. The filter elements, stretched via locking fasteners, are easy to maintain and can be removed from the front.

In particular the cleaning device consists of:

- Impulse fan

- Impulse transmitter

- Connection ducts

- Cleaning trolley

- Drive gear