For an existing aerated concrete factory in England HESS AAC (a member of the Top-Werke Group) has ordered an autoclave transfer car from Münstermann. The transfer car is designed for the loading and unloading of autoclaves.

Implementation by Münstermann

We have completed the entire implementation of the project in-house. It began with the measurement of the existing foundations on site by the project leader, the design and development in our Design Office and the assembly in our production halls. We also completed the electronic control system and the entire cabling of the unit.

Acceptance by HESS AAC and the end-customer presented no problems and was carried out to their complete satisfaction on one day. Additional rails were fitted beside the transfer car so that the kiln cars, which had been supplied by the customer for us, could be further processed. By transporting the transfer car in two large components it was possible keep to the tight schedule of the end-customer’s factory shutdown by the quick assembly and commissioning.

Technical details

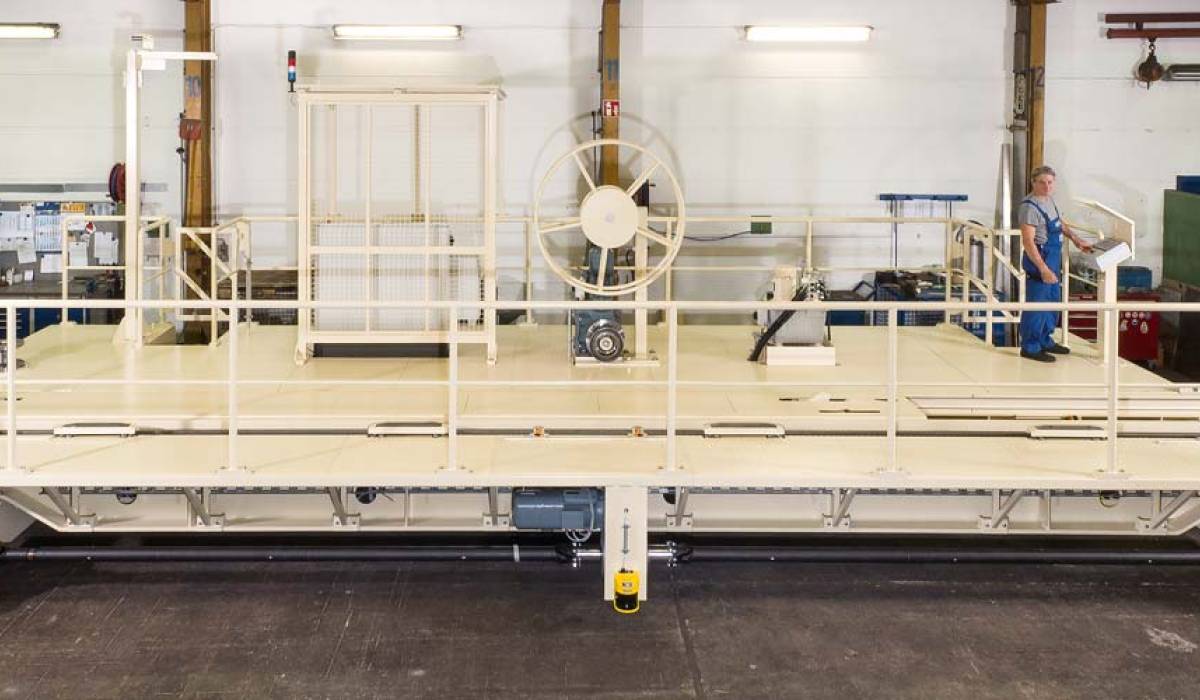

The transfer car (viewed from the direction of travel) is 11metres long and 4 metres wide. The load capacity of the transfer car is almost 20 tonnes. The product is processed on bogeys. 4 bogeys can be processed at the same time on the transfer car. In addition here the transfer car is fitted on both sides with a pick up and pulling conveyor system. The conveyor has a thrust and traction force of 55 tonnes and in each case is therefore in a position to transport 22 bogeys in the autoclave and extract them. No supporting structures or additional rails in the autoclave and rails on the long side for the conveyor are required.

As in the autoclave the bogeys are connected together by hooks and a hydraulically- operated decoupling is fitted to the transfer car. This separates the connected train of bogeys in the autoclave into single trains of four cars, which then are driven off the transfer car. In order to bridge the gap between the transfer car and the opening in the autoclave the transfer car is equipped on the autoclave side with a hydraulically operated flap bridge.

Besides this a cable winch was fitted at the request of the customer (see illustration below). The winch is for pulling the bogeys out of the autoclave if the mechanical hooks between the bogeys become unintentionally disconnected. The cable is unwound manually and secured by the operator to the bogey. The cable is then wrapped around a cable drum via a pulley and the bogeys are hauled out of the autoclave.

Safety aspects

The transfer car is accessible across the entire width over an operator’s platform (see stairway in the illustration below). To reach the transfer car stairs and railings are installed on both sides with safety latched access doors. As protection for the gangways a laser scanner is installed on both the end faces of the transfer car.