An important system component part of the plant is the mould oiling station for the casting moulds. These casting moulds are oiled so that the aerated concrete blocks are later easily released from the moulds. This process can be compared with the greasing of a baking tin. Nevertheless the process here runs fully automatically and the casting moulds are sprayed with special mould oil before the filling with the mortar mixture.

The bank of nozzles is lowered for this reason into the casting mould and moves in a longitudinal direction. At the same time the whole of the interior surface of the mould is moistened with the mould oil in one step. Should you wish to see a demonstration film of the method of operating, you can contact us.

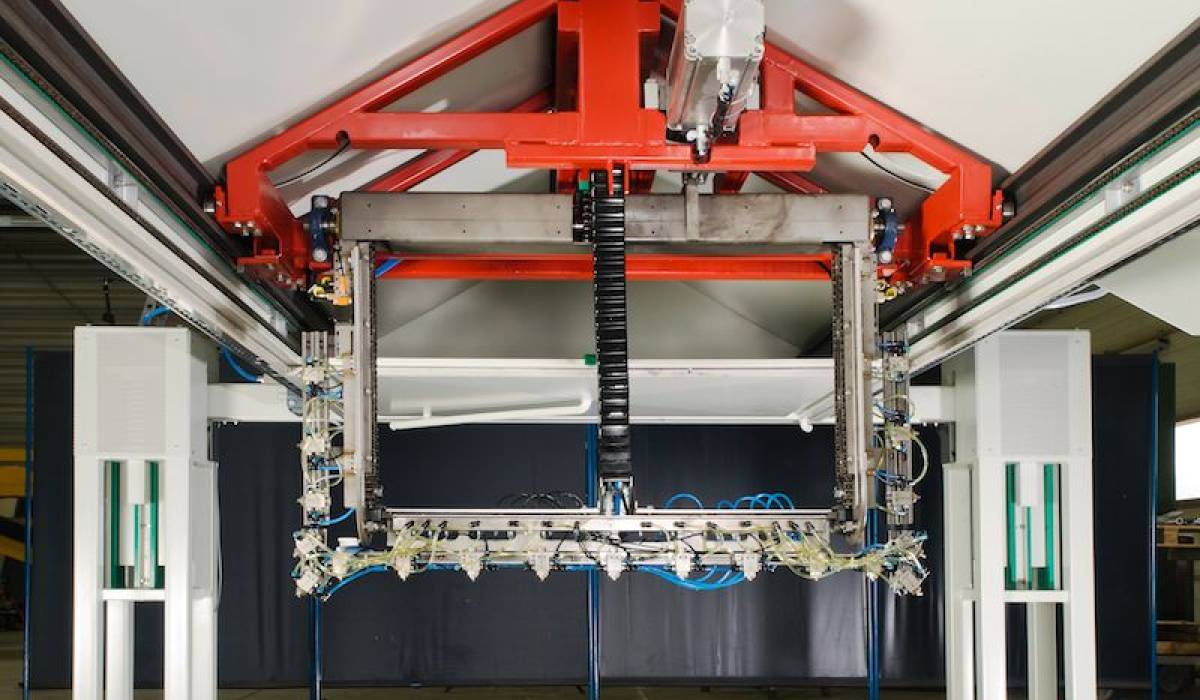

Bank of nozzles for the mould oiling unit

The bank of nozzles for the spraying of the interior surfaces of the casting moulds has a variable design. The width of the nozzles can be adjusted therefore as required by means of a fine-dosing system including the angle of the nozzles. This guarantees that the interior surfaces of the casting moulds can be completely covered. The supply of the oil can be temporised in order to ensure an even viscosity of the mould oil. During the spraying of the casting moulds fine oil vapour is developed. This oil vapour is fed back into the process by an extractor system.