This project concerns a complete material handling system for kiln cars for a large Spanish producer of heavy clay products. In this new factory tiles and stoneware tiles for example are produced.

Realisation of the handling system

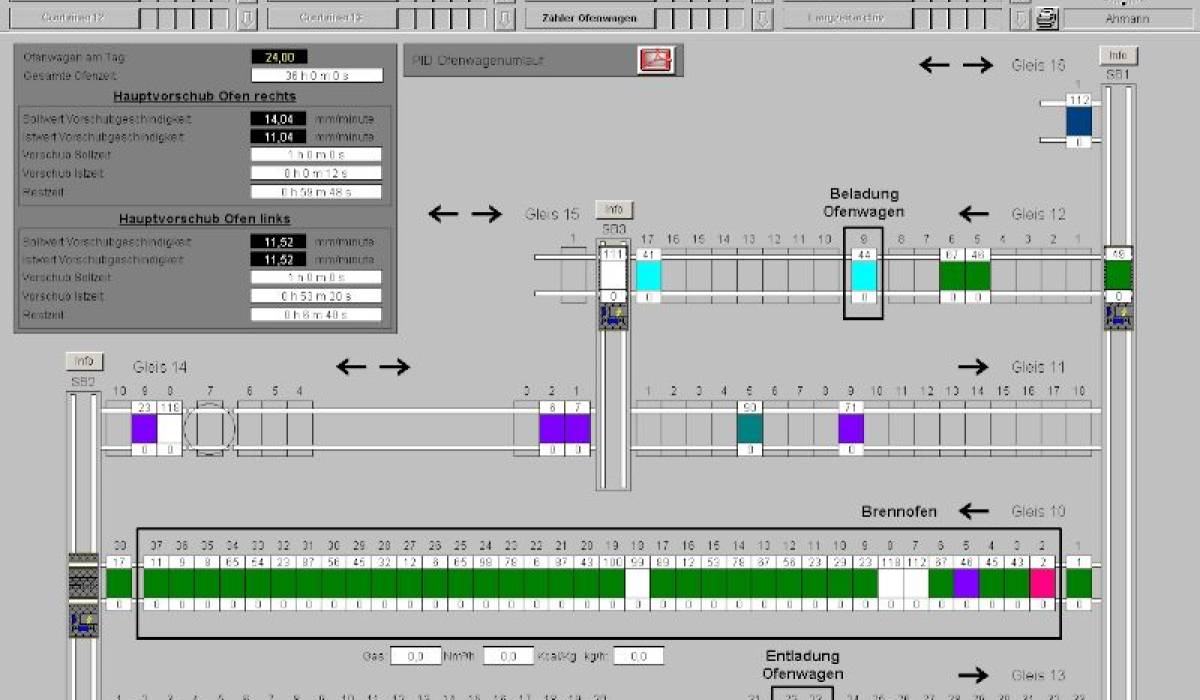

The total scope of the order included along with the components for the material handling system also the complete electrical control system of the unit including the electrical and mechanical assembly work. Together with the actual handling system for the kiln car circuit (consisting of transfer cars, a turntable, a feeder system and various chain and cable conveyors) a centralised control system with visualisation of all processes were for this reason designed, developed and installed.

As the highest degree of automation in the handling system is required, Münstermann designed the centralised control system. The control system of the remaining system sections such as the dryer, the setting section or the oven itself was integrated into the central control system.

Visualisation and the control concept

Part of the visualisation is the development of the overall overview from the entrance to the dryer to the extraction of the material from the kiln car circuit. In particular the following reviews are presented: track system of the kiln cars, dryer overview, material handling system, the loading and unloading stations, the track system of the kiln car circuit, the kiln and also more general images. As well as the creation of a complete total overview a multitude of individual overviews can also be resorted to.

In addition to the possibilities of visualisation, status request of the appropriate sensors and set point updates can of course be undertaken. All values can be transmitted in a SQL- data bank format to a PC for filing and further processing (e.g. printouts and reports).