Measure and analyze

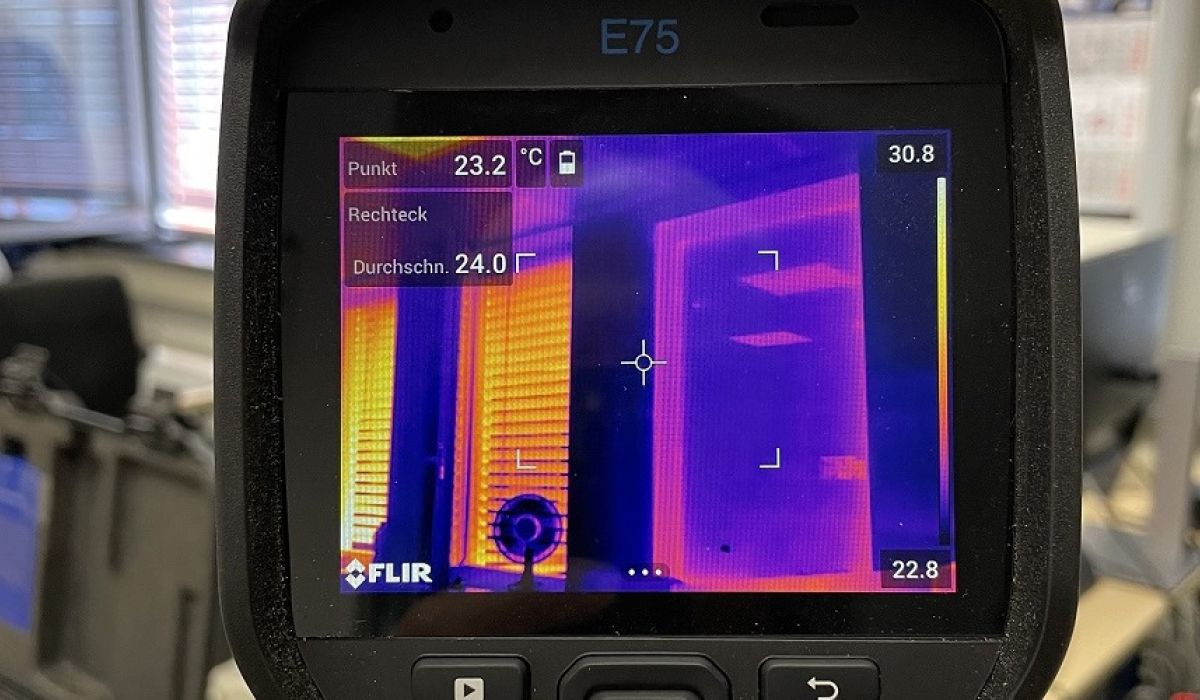

A wide variety of measuring equipment is used, each of which is matched to the components and requirements. For example, we use an X-ray fluorescence analysis device to determine / test metals / alloys or a coupling measuring device to align shafts and couplings.

For simple geometric applications, we use distance lasers, cross line lasers, theodolites, digital and analog leveling devices, among others. For more complex geometric applications, e.g. a precision rotary level, a total station or a laser tracker are used.

A selection of our measuring instruments is shown below.