Together with our customers from the foundry industry Münstermann has developed a new cooler concept, in which the required air supply is considerably reduced.

Much less cooling air

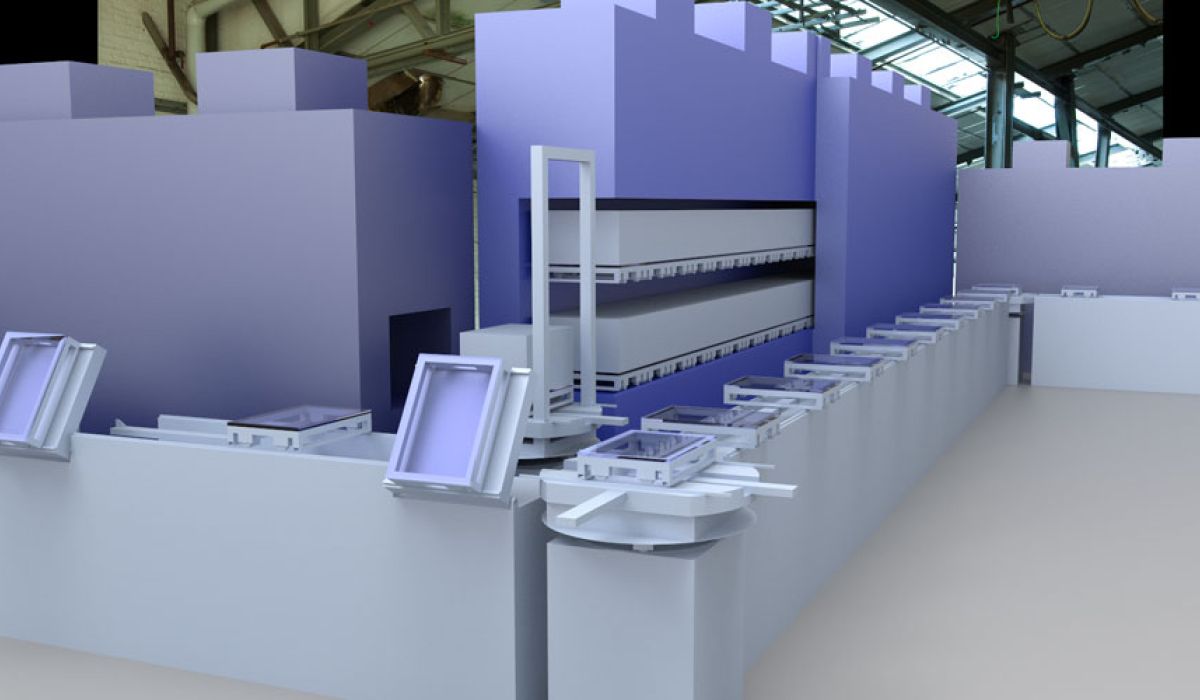

The casting shells have to be cooled down to 30-50 °C due for the following step in the production process. The new cooler consists of 10 cooling zones, which are divided up into three individual coolers of similar size, in which the moulds are streamed with cooling air by integrated air distributor devices. The transmission of the cooling air takes places at two stages. The distribution of the cooling air and also the two-tier design are dependent on the local structural conditions and are a good example of what we understand by customer-orientated design.

With a special design version of the air ducts with the integrated airflow distributors the air is screwed as in two parallel corkscrews from Zone 10 to Zone 1. The result is a considerable saving of the air needed.

Automation and transportation: discharge of sand from the cooler

It is necessary to provide sand discharging devices, as sand falls from the moulds as well as from the airflow in the cooler. Münstermann has made provision for a vibration channel immediately under each cooler. The transportation through the cooler and the loading and unloading is also a part of the overall cooling concept.

Please contact us.

We believe we have developed a very interesting cooling concept. Details we would like to pass on during a personal meeting. Please contact Uwe Schwinhorst without any obligation for further information.