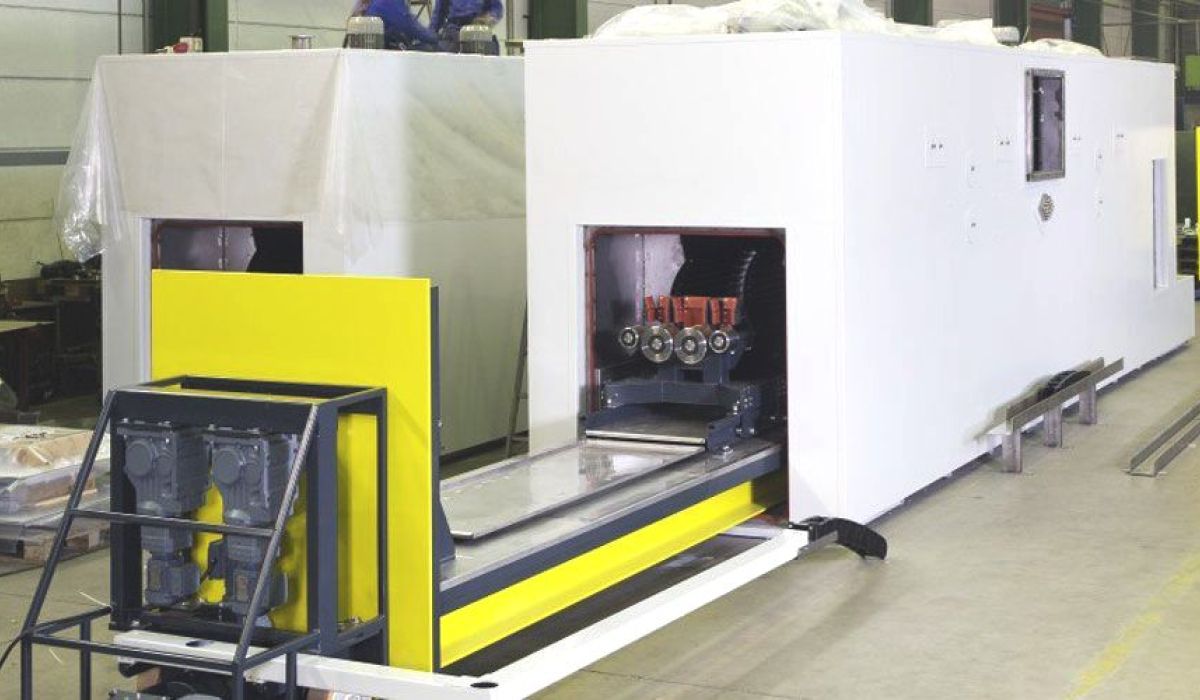

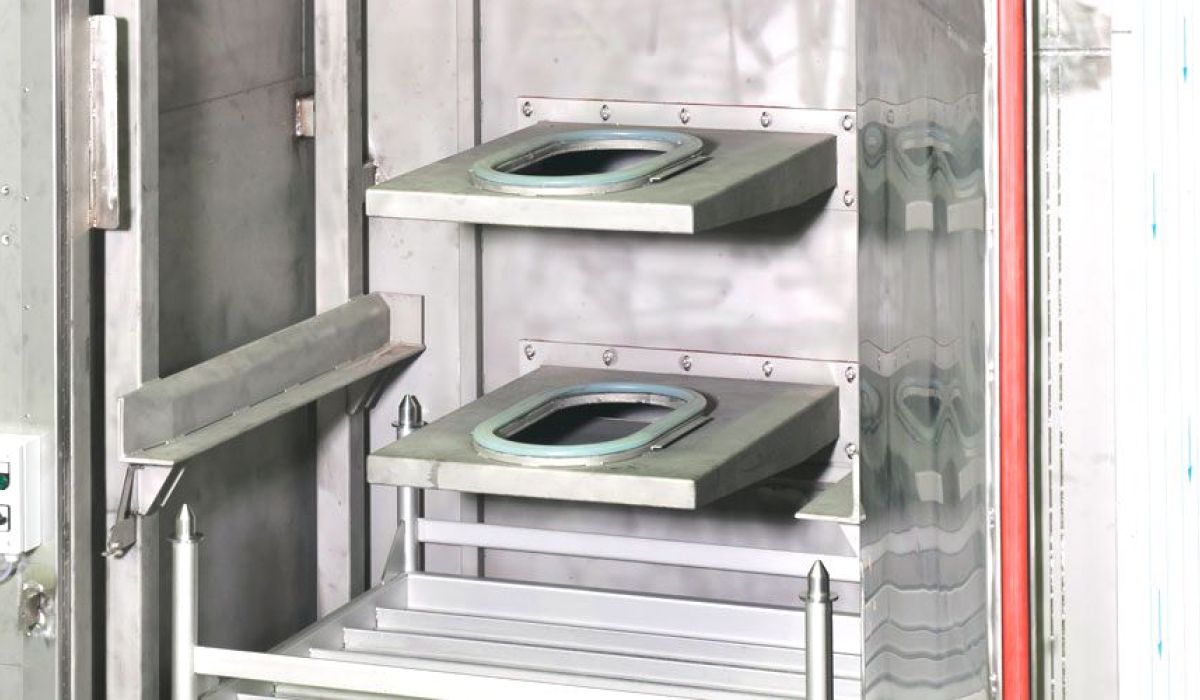

Oven for the continuous heating of the metal strips

A current example in a metal strip production line shows how Münstermann’s experience in intelligently conceived details is implemented and how these details lead to a more efficient production process.

Read more …